2nd Dec 2024

9 Important Regulations To Know in the Food Industry

The food industry is one of the most globally regulated sectors, with numerous guidelines in place to maintain safety and quality. In the United States, the Food and Drug Administration (FDA) oversees the safety of much of the nation’s food supply, setting standards and implementing regulations that companies must follow.

A thorough understanding of these regulations is crucial for purchasing agents and inventory buyers. Compliance is the cornerstone of upholding public safety and maintaining a company’s reputation.

Tools like meter charts, circular chart paper, and chart recorders help businesses adhere to FDA food regulations. The following guide outlines nine important regulations to know in the food industry and explores how monitoring tools contribute to regulatory compliance.

1. FDA Food Safety Modernization Act (FSMA)

The Food Safety Modernization Act (FSMA) is a landmark regulation that shifted the focus of the FDA from responding to food contamination to preventing it. The FSMA requires companies to develop comprehensive food safety plans that identify potential hazards and preventive controls.

Inventory buyers and purchasing agents are key in sourcing materials that meet FSMA standards. Many companies use chart recorders to monitor temperatures and other critical conditions, helping them meet regulatory standards. Chart recorders provide a real-time visual record that helps companies keep their processes within FDA-approved safety limits, especially during storage and transportation.

2. Good Manufacturing Practices (GMPs)

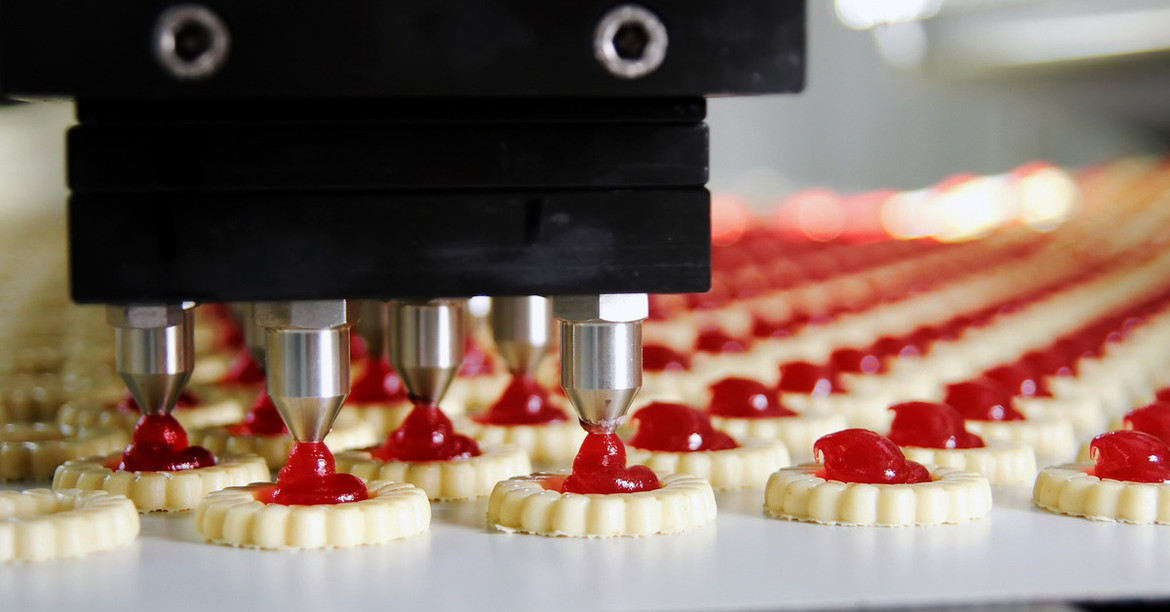

Good Manufacturing Practices (GMPs) are essential guidelines in the food industry to produce and control products consistently according to quality standards. The FDA mandates that food manufacturers comply with GMPs to minimize contamination risks, labeling errors, and food adulteration.

GMP compliance extends across various areas, including equipment cleanliness, hygiene, and facility maintenance. For purchasing agents, sourcing equipment that facilitates GMP compliance is key.

Meter charts are instrumental here, as they document data that shows whether equipment, such as freezers and refrigerators, functions within the required standards, reducing potential risks of noncompliance.

3. Hazard Analysis and Critical Control Points (HACCP)

Hazard Analysis and Critical Control Points (HACCP) is a systematic approach focused on identifying and controlling potential hazards in the food production process. HACCP is especially relevant for food companies that deal with perishable items like dairy, meat, and seafood.

The FDA enforces HACCP requirements, particularly in high-risk sectors, to prevent contamination. Companies use chart recorders and circular chart paper to track critical control points, such as cooking and refrigeration temperatures, helping every batch meet FDA standards. These charts act as reliable documentation of safe food-handling practices, which are essential in the event of an FDA audit.

4. Food Allergen Labeling and Consumer Protection Act (FALCPA)

The Food Allergen Labeling and Consumer Protection Act (FALCPA) mandates that food labels identify the presence of the eight major food allergens: milk, eggs, fish, shellfish, tree nuts, peanuts, wheat, and soybeans. Inventory buyers and purchasing agents remain vigilant when selecting raw materials and ingredients to ensure allergen labeling compliance.

Mislabeling could result in serious health risks and penalties. To assist with compliance, food processors use meter charts to track ingredient sources and production processes, reducing the risk of allergen cross-contamination.

5. Preventive Controls for Human Food

Under FSMA, the FDA requires food companies to establish preventive controls for human food, focusing on anticipating and mitigating contamination risks. These controls include monitoring critical factors such as time, temperature, and humidity.

Circular chart recorders are essential in documenting these parameters, providing detailed records that FDA inspectors can review. These records verify that companies consistently adhere to food safety protocols. For purchasing agents, sourcing the right monitoring tools is crucial for maintaining compliance with preventive control regulations.

6. Sanitation Standard Operating Procedures (SSOPs)

Sanitation Standard Operating Procedures (SSOPs) are FDA-mandated protocols designed to keep food production facilities clean and sanitized. SSOPs are a critical part of preventing contamination during food processing.

Compliance with SSOPs is mandatory, and companies must have detailed records that prove they meet the requirements. Chart recorders and meter charts assist with tracking data like water temperature during cleaning cycles or chemical concentrations, ensuring each sanitation process aligns with FDA standards. This level of documentation helps food organizations meet compliance requirements and establish reliable sanitation practices.

7. Cold Chain Compliance for Perishable Goods

Maintaining the cold chain is essential for preventing spoilage and contamination of perishable goods like meats, dairy, and seafood. The FDA mandates that companies monitor temperatures during storage and transportation to protect public health.

Chart recorders are vital in cold chain compliance, as they continuously monitor and document temperature conditions. Purchasing agents can maintain their company’s compliance by investing in reliable chart recorders and circular paper for consistent data tracking. This ongoing monitoring prevents costly spoilage, maintains product quality, and assures customers of the product’s freshness.

8. Traceability Requirements for Food Safety

Traceability allows companies to track food items throughout the supply chain, from production to final sale. The FDA has implemented traceability requirements for high-risk foods, mandating that companies have clear records of each product’s origin, production, and distribution.

Chart recorders and meter charts can assist by providing an ongoing record of environmental conditions affecting products. This data aids companies in verifying the safety and quality of their products and supports rapid responses in case of a recall. Traceability is essential for purchasing agents and inventory buyers, as they must choose suppliers providing this level of transparency and compliance.

9. Labeling Requirements for Packaged Foods

The FDA has stringent labeling requirements designed to give customers accurate information about the food they purchase. Labels must include nutritional information, serving size, ingredients, and allergen declarations.

Quality control teams can use meter charts and chart recorders to validate that products meet labeling standards. Compliance with FDA labeling regulations builds consumer trust and prevents potential legal issues from mislabeling or lack of transparency.

Recorders Charts & Pens: How Our Products Help With Compliance

For purchasing agents and inventory buyers, sourcing tools like meter charts, circular chart paper, and chart recorders are essential for maintaining regulatory compliance. Meter charts track crucial parameters, such as temperature and humidity, which affect product safety.

Circular chart paper provides a continuous record of environmental conditions, helping companies meet FDA requirements, especially during audits. Chart recorders offer a real-time snapshot of conditions in storage or during transport for compliance with FDA mandates on cold chain and traceability.

Together, these tools simplify regulatory adherence, minimize noncompliance risk, and provide peace of mind for companies and consumers. You can find these tools and more at Recorders Charts & Pens.

Understanding the important regulations to know in the food industry is critical for maintaining product quality and safety while avoiding penalties. The FDA enforces numerous rules, from food labeling to cold chain compliance, requiring meticulous attention to the requirements. Purchasing tools like chart recorders, meter charts, and circular paper from Recorders Charts & Pens allows companies to document compliance and provide proof of adherence.