Posted by RCP on 29th Jul 2025

Benefits of Automating Data Collection in the Food Industry

You can’t just sell any food to customers. Your products must meet strict quality standards and regulations set by authorities. These standards and regulations ensure your food is safe for consumers and that it meets certain nutritional requirements.

Of course, many factors can impact the quality of food, such as the ingredients used, production processes, storage conditions, and more. Manually tracking all these factors for each product would require significant time and resources.

Therefore, many food companies are turning to technology for assistance. Automated data collection using chart recorders, sensors, and software can help businesses monitor and control various aspects that affect food quality. Discover the benefits of automating data collection in the food industry to enhance your business.

Save Time

Why waste time manually recording data when you can have technology do it for you? Your business can save valuable time and resources that it can use elsewhere in the production process by implementing automated data collection.

Wouldn’t it be great to have extra help with quality control or customer service tasks that aren’t as easy to automate? With automated data collection, your team can focus on the bigger, more important parts of your business.

Save Money

Automated data collection tools come with an upfront cost, and sometimes, this cost can be considerable. As a result, businesses may hesitate to invest in these tools, especially if they have existing manual processes in place.

However, automated data collection can help businesses save money in the long run despite the initial cost. By streamlining processes and minimizing errors, businesses can reduce costs associated with manual data collection, such as printing, shipping, and labor expenses. Additionally, businesses can make better informed decisions that can potentially lead to increased profits and cost savings by having more accurate and comprehensive data at their disposal.

Less Labor

Automated data collection can also reduce the amount of labor required for data entry and management. With manual processes, businesses must allocate employees or even hire dedicated staff solely for data collection and entry tasks. This allocation increases labor costs and reduces the availability of employees for other tasks or projects.

Businesses can reduce the need for additional labor and free up employees to focus on more valuable work by utilizing automated data collection methods.

Less Waste

You can take immediate action to rectify the situation if you discover that the temperature or humidity in your storage area isn’t optimal for a particular product. This knowledge reduces the risk of spoilage and waste due to improper storage conditions. With automated data collection, you can monitor temperature and humidity levels in real-time and receive alerts if fluctuations occur outside the desired range.

Higher Accuracy

You have some incredibly talented employees working for you, but let’s face it—humans make mistakes. No matter how detail-oriented your team may be, there’s always a chance for human error when manually collecting data. By using automated data collection methods, you can eliminate the risk of human error and increase the accuracy of your data.

With manual data collection, there’s also a possibility for inconsistencies in how information is recorded. For example, one employee measuring an item in inches while another recording it in centimeters can lead to data discrepancies. Automated data collection keeps all measurements and entries consistent, resulting in more reliable and accurate data.

Real-Time Data

If a refrigerated food item’s temperature rises above safe levels, you must know about it immediately to prevent potential food safety issues. With automated data collection, you can receive real-time updates on temperature readings and other important data, allowing you to respond quickly and effectively to any issues that may arise.

Staying Compliant

Businesses in the food industry are subject to strict regulations and guidelines. Failure to meet these standards can result in fines, legal action, and reputational damage. Automated data collection can help businesses stay compliant by providing accurate, real-time data that they can use as evidence of their compliance.

Moreover, automated data collection can also assist with tracking and tracing products in case of a recall. In the event of contaminated or unsafe food, businesses must quickly identify affected products and remove them from shelves. Automated data collection quickly and accurately identifies affected products, allowing businesses to take swift action and minimize the potential harm to consumers and their reputation.

Improved Safety

Another benefit of automating data collection in the food industry is that it can improve safety; not just for customers, but for your employees, too. With automated data collection, there’s less manual handling of products and less room for human error, reducing the risk of injuries or accidents in the workplace. Additionally, businesses can ensure they sell only safe and fresh products to customers by accurately tracking expiration dates and other important information.

What Tools Can You Use for Automated Data Collection?

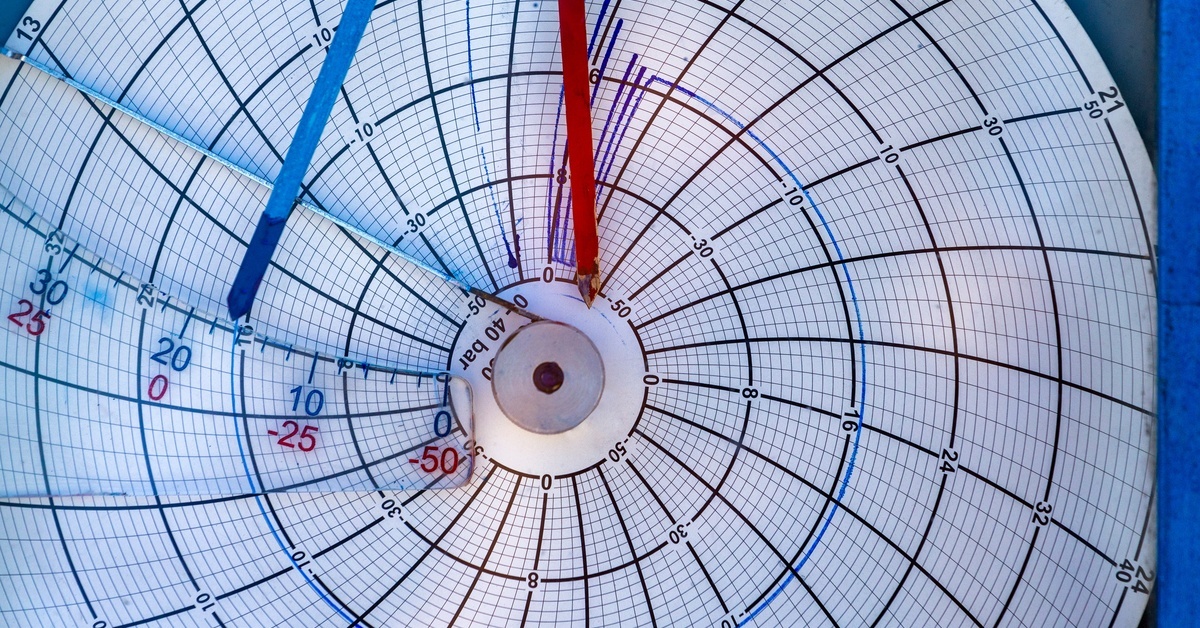

Some popular tools for automated data collection in the food industry include chart recorders, sensors, software, and more. Chart recorders are devices that capture data on a chart, such as temperature and humidity. Businesses can use chart recorders to monitor the storage and transport conditions of food products.

A sensor is another tool that businesses can use for automated data collection. Sensors are devices that collect data on physical and chemical properties, such as temperature, pH levels, and air quality. You can place these sensors in different areas of a production facility or storage area to track conditions and identify potential issues. Some sensors can even send alerts if certain conditions exceed predetermined thresholds, which allows for timely corrective actions.

Software is also an important tool for automated data collection in the food industry. Businesses can gather, store, and analyze large amounts of data collected from various sources using the proper software, allowing for easier food safety and quality tracking and monitoring.

Recorders Charts & Pens specializes in chart recorder supplies, including chart recorders, chart paper, and recorder pens. You can use our products to track and monitor temperature, humidity, and other factors that affect food safety and quality. Our supplies are high-quality, built to last, and will help you automate your processes so you can focus on providing the best quality food to your customers. Shop now and streamline your data collection process!