Posted by RCP on 20th Feb 2026

How To Ensure Food Safety Compliance in Your Facility

Food safety compliance protects your customers, your brand, and your bottom line. In dairy, beverage, and food processing environments, even small gaps in monitoring or documentation can lead to recalls, fines, or production shutdowns.

Purchasing agents and inventory buyers play a critical role in maintaining compliance. When you understand the systems, supplies, and processes that support safe production, you strengthen your entire operation. Discover how to ensure food safety compliance in your facility with clear, practical steps.

Establish Food Safety Standards and Procedures

You can maintain food safety compliance when you define expectations in writing and align them with regulatory requirements. Every facility should follow FDA regulations, current Good Manufacturing Practices (cGMPs), and any applicable HACCP plans.

Document each process that affects food safety, including temperature control, pressure monitoring, sanitation, storage, and transportation. Make these procedures accessible to supervisors and line operators, and review and update your documentation on a regular schedule. When regulations change or production lines shift, revise your procedures immediately to maintain compliance.

Monitor Critical Control Points With Accurate Instruments

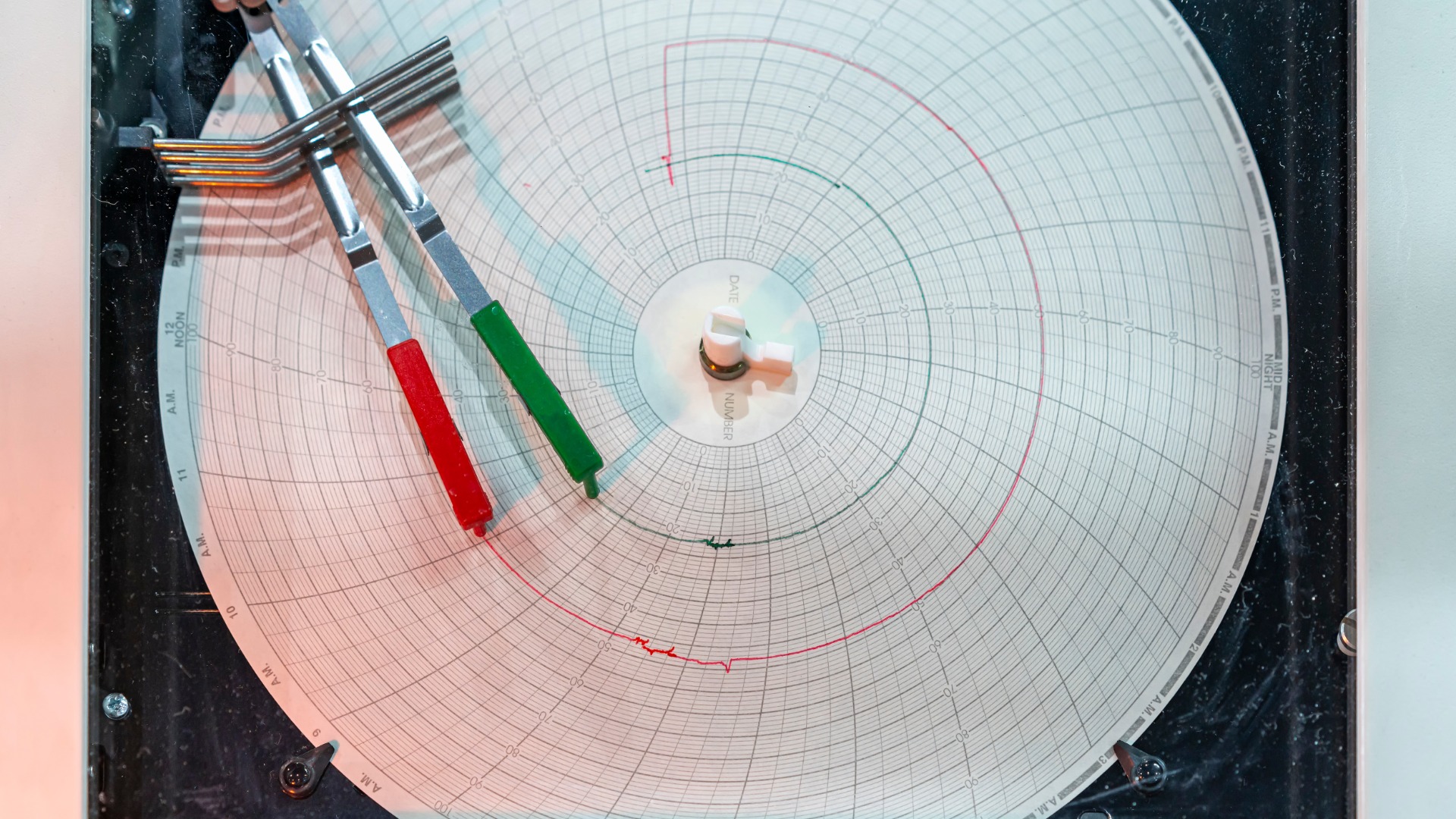

Monitoring every critical control point with reliable equipment aids compliance. Temperature, pressure, humidity, and time all influence food safety in processing environments. To accomplish this, you can install calibrated recording instruments in areas like pasteurization lines, storage coolers, retorts, and fermentation tanks. Continuous monitoring provides proof that your processes stay within safe limits.

Facilities that still rely on circular chart recorders or strip chart systems must keep those devices in proper working order. Using high-quality recorder charts and compatible pens ensures that data remains legible, accurate, and audit-ready. Clear recordings protect a facility during inspections and internal reviews.

Maintain Detailed and Organized Documentation

You can protect your operation by maintaining organized, complete records. Regulatory agencies expect clear documentation that demonstrates consistent control over food safety hazards. Keep logs for temperature, pressure, cleaning cycles, equipment maintenance, and corrective actions. Store both physical and digital records in a structured system that allows for quick retrieval.

Auditors often request documentation from specific dates or production runs. When your team can produce accurate records within minutes, you show that your facility values transparency and accountability.

Train Employees on Food Safety Protocols

You strengthen facility compliance when you train employees at every level. Operators, maintenance staff, supervisors, and quality teams all influence food safety outcomes.

Provide onboarding training that covers sanitation procedures, monitoring requirements, and documentation standards, and reinforce those expectations with ongoing refreshers and updates. Encourage employees to report irregular readings, equipment malfunctions, or procedural gaps immediately. A well-trained workforce identifies risks early and prevents small issues from becoming major violations.

Perform Routine Equipment Inspections and Maintenance

It is critical to keep equipment in optimal condition for food safety. Worn components, clogged sensors, and outdated parts can compromise accurate monitoring.

Create a preventive maintenance schedule for recorders, sensors, valves, and sanitation systems. Replace consumable components, such as pens or chart paper, before they degrade data quality. Work with a reliable supplier that maintains strong inventory levels for recorder parts and accessories—quick access to FDA-approved recorder brands and compatible supplies helps you avoid downtime and maintain compliance.

Conduct Internal Audits and Correct Issues Quickly

You can stay ahead of regulatory problems by conducting internal audits on a regular basis. Audits allow your team to verify that processes match documented procedures. Review monitoring logs, maintenance records, and sanitation documentation to compare actual performance against established limits and identify gaps.

When you find a deviation, document the issue and implement corrective action immediately. Track the resolution and confirm that the solution prevents recurrence. Proactive audits reduce the risk of costly enforcement actions.

Control Inventory and Supply Chain Risks

You support food safety compliance when you manage your inventory and supply chain with precision. Shortages or incorrect parts can interrupt monitoring systems and weaken documentation.

Maintain sufficient stock of critical consumables and replacement parts—this includes chart paper, pens, ribbons, and recorder components that support continuous monitoring. Working with a centralized supplier with expertise in food processing instrumentation simplifies purchasing. When you source from a knowledgeable partner, you reduce compatibility errors and protect the integrity of your recording systems.

Align Purchasing Decisions With Compliance Goals

Aligning purchasing decisions with regulatory and operational requirements drives compliance forward. Buyers influence which brands, models, and supplies enter the facility.

Evaluate products based on compatibility, FDA approval, durability, and performance, and avoid substituting components that may compromise calibration or recording accuracy. Collaborate with quality assurance and maintenance teams before placing large orders. This cross-functional communication ensures that your purchases support long-term compliance and operational stability.

Strengthen Communication Across Departments

As mentioned, you can reinforce food safety compliance when you make sure that all your facility’s departments communicate clearly. Production, maintenance, purchasing, and quality assurance teams must all work together to maintain safe operations.

Hold regular meetings to review monitoring trends, equipment performance, and upcoming inspections. Share documentation requirements and regulatory updates across teams. It’s also important to encourage transparency. When employees understand how their roles support food safety compliance, they take greater ownership of their responsibilities.

Prepare for Regulatory Inspections With Confidence

You can reduce stress during inspections when you prepare your facility and teams in advance. Inspectors expect organized documentation, calibrated equipment, and knowledgeable staff.

Keep your monitoring systems up to date and verify calibration certificates. Confirm that recorder charts remain legible and that your logs show consistent oversight. Additionally, you should train supervisors to explain processes clearly and provide requested documentation promptly. Preparation demonstrates professionalism and a commitment to food safety standards.

Build a Reliable Foundation for Food Safety Compliance

You can ensure food safety compliance in your facility by combining strong procedures, reliable monitoring, thorough documentation, and informed purchasing decisions. Each element supports the others. When you invest in accurate instruments, maintain adequate inventory, and partner with knowledgeable suppliers, you protect both your production line and your reputation.

Food safety compliance does not depend on a single department. It requires team coordination, attention to detail, and consistent follow-through. With structured systems and dependable supplies in place, your facility can meet regulatory expectations and maintain operational excellence.