7th Nov 2023

How To Properly Service Your Chart Recorders

Chart recorders are exceptional pieces of equipment used to monitor and record information across an array of industries. However, these devices require time and care to function correctly. Continue reading to learn everything you need to know about how to properly service your chart recorders.

Check the Wiring Connection

The integrity of the wiring connection is paramount in ensuring the efficacy of your chart recorder. Begin by turning off the chart recorder to eliminate any safety risks. Then, look for signs of fraying, breakage, or discoloration. These signs could indicate a defect in the wire, which may lead to inaccurate readings or device malfunctions.

Next, check the tightness of the connections. Loose components can cause intermittent contact, resulting in inconsistent data. Make sure all wires are securely attached to their respective terminals.

Finally, use a multimeter to perform a continuity test. This test will help you detect wiring issues that are undetectable to the naked eye. If you find issues during this check, replace the faulty wire immediately. The proper wiring connection will maintain accurate readings and prolong the chart recorder’s life span.

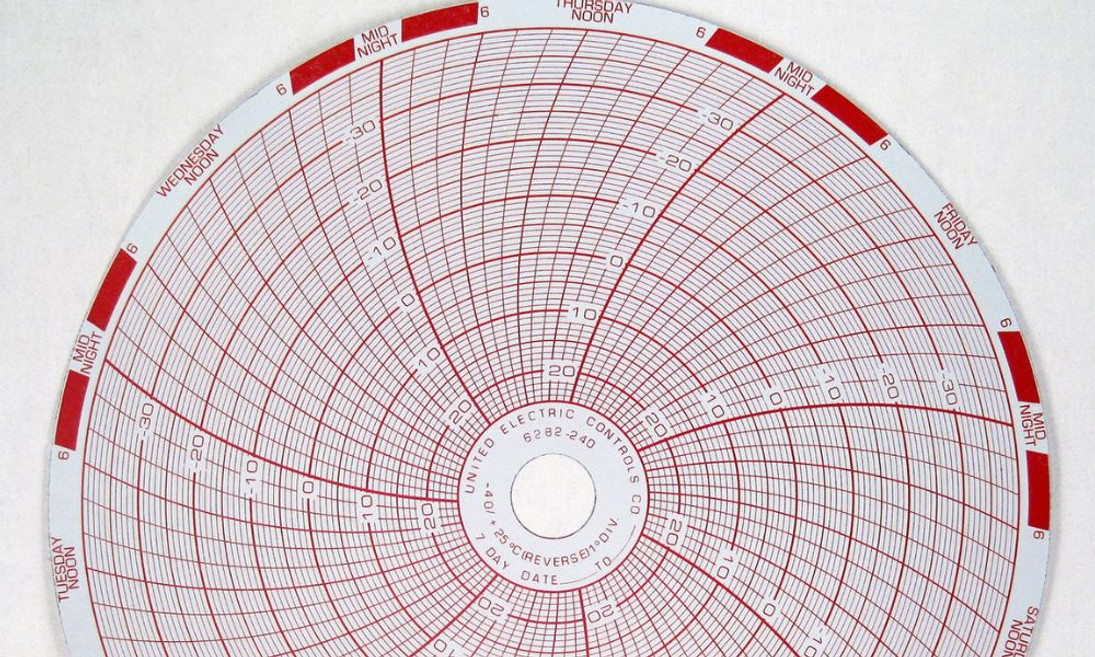

Inspect the Recording Paper

Circular chart recorder paper is the key to impeccable and accurate data collection. Look for signs of discoloration, fading, or ink blotches, as these can lead to data inaccuracies. Furthermore, confirm that you have correctly loaded the recording paper into the device.

Misalignment or improper installation can sometimes cause the recorder to display errors or inconsistent readings. Maintain a regular schedule for replacing the recording paper to ensure optimum recording.

Examine the Pen Movement

Visually inspect the pen movement during operation. It should traverse the recording paper smoothly, without deviation or stutter. If you notice that the pen is skipping or stuttering, something is interfering with its motion.

Fix Erratic Pen Movement

Start by checking for any visible obstructions or buildup of sticky residue hindering the pen's motion. Use a dry cloth to clean the pen and its surroundings.

If issues persist, consider replacing the pen; it could be worn out or damaged. Always remember to carefully align the new pen according to the manufacturer's instructions.

Calibrate the Chart Recorder

Calibrating a chart recorder is a meticulous task that demands precision. To begin, select a trusted standard instrument as your calibration benchmark. Connect the chart recorder and the standard instrument, running them simultaneously. Compare and record the readings from both devices. If there is a discrepancy beyond the acceptable limit, it's time to adjust the chart recorder.

Remember that calibration is an ongoing task, so you must regularly calibrate your chart recorder to uphold accuracy and reliability. Establish a calibration schedule based on usage frequency and the nature of the recorded data. For critical processes with continuous chart recorder usage, more frequent calibration may be necessary. Always document calibration results for future reference, auditing, or troubleshooting purposes.

Clean the Device

You need to be methodical and careful when cleaning your chart recorder to ensure you do not damage any component. Always switch off and unplug the device before you start cleaning.

Use a soft, dry cloth to wipe the exterior of the chart recorder. Dust and debris can accumulate over time and may cause issues if left unchecked. Do not use any kind of liquid or chemical cleaner on the exterior, as this could potentially damage the casing or seep into the internal mechanisms.

Next, remove the chart paper and pen. Use a soft, slightly damp cloth to clean the pen, removing any ink residue that could interfere with its smooth movement. Allow the pen to air dry before reinstalling it.

Use a can of compressed air to clean the interior of the chart recorder, including the recording mechanism. This will help remove dust and debris from the intricate parts without causing any damage. Be sure to follow the manufacturer's instructions for using compressed air, as improper use can lead to damage.

Lastly, before reinstalling the chart paper, ensure all parts are completely dry. Moisture can negatively affect the functioning of the device and the accuracy of the recordings.

Apply a Lubricant to Stiff Components

Not all lubricants are equally as effective. You will need a high-quality lubricant that’s compatible with your chart recorder model and electronic devices.

Typically, a silicone-based lubricant is recommended for chart recorders. It’s an excellent choice due to its water resistance, wide temperature range, and superior film strength. Silicone lubricants are also less likely to damage plastic or rubber components, which are often found in the pen mechanism of chart recorders.

Here’s what you need to know to apply the lubricant:

- In addition to the lubricant, you’ll need a small brush or swab and a soft, clean cloth.

- Disconnect the chart recorder from the power source.

- Remove any screws or fasteners. Open the casing to reveal which components need lubricating.

- Dip the brush or swab in the lubricant and gently apply it to the moving parts of the recorder. These typically include the pen mechanism, the drive gears, and other rotating parts. Avoid over-lubrication, as this could lead to residue build-up or seepage onto areas where lubrication is not desired.

- Use a soft cloth to wipe away any excess lubricant. Ensure no residue is left on the components, as it can attract dust and gunk that impede operation.

- Reassemble and test the chart recorder to ensure it functions smoothly.

Bonus Tips for Easy Servicing

Beyond routine maintenance and calibration procedures, you should adhere to several other best practices to enhance the longevity and reliability of your chart recorder.

Document All Maintenance

Keeping a detailed log of all maintenance activities can be beneficial for identifying recurring issues and determining the appropriate servicing intervals. This record can also be useful for troubleshooting issues, conducting a performance evaluation, and maintaining compliance with industry standards.

Store Chart Recorders Properly

Store chart recorders in a clean and dry environment when not in use. This can prevent dust accumulation and moisture exposure, which can lead to corrosion and other damage over time. Additionally, avoid exposing your chart recorder to extreme temperatures, as this can affect its performance and lifespan.

Maintain an Inventory of Spare Parts

Keep spare parts like recording paper, pens, and batteries on hand. This can save you from substantial downtime in critical operations in case of sudden malfunctions.

Learning how to properly service your chart recorder is essential for the longevity of the equipment. Applying these best practices will guarantee the chart recorder is ready to function accurately.