2nd Aug 2024

The Importance of Pharmaceutical Environmental Monitoring

The quality and safety of pharmaceutical products is paramount from creation to when the items reach the shelves of stores. Data monitoring is a useful approach that regulates conditions, prevents deviations in production, and produces high-quality products. Find out the importance of pharmaceutical environmental monitoring from the data collection tools to the aspects monitored to the risks involved.

The Essential Types of Environmental Data To Collect

Establishing a controlled environment that develops reliable and potent pharmaceuticals is impossible without data monitoring. Read through the most valuable components to monitor when it comes to pharmaceutical creation, storage, and transportation.

Temperature

Elevated temperatures can degrade active pharmaceutical ingredients (APIs) and excipients, while low temperatures can lead to precipitation or crystallization in liquid formulations. Consistently monitor ambient temperatures in storage areas and manufacturing zones using calibrated thermometers and chart recorders for precise readings.

Ensure temperatures stay within specified ranges: between 15°C and 25°C for room temperature settings and between 2°C and 8°C for cold storage. Implement automatic alarms to notify personnel if temperatures deviate from set limits so that they can take swift corrective actions.

Humidity

Low humidity can cause static electricity issues and affect tablet coating processes. Use hygrometers to continuously monitor relative humidity levels.

Overall, keep humidity levels between 30 and 50 percent RH. Dehumidifiers and humidifiers can contribute to optimal conditions alongside tools that regulate airflow.

Airflow Rates

Monitoring airflow rates maintains good air quality and prevents cross-contamination. Measure airflow rates in cleanrooms and other critical areas using anemometers. Then, ensure that High-Efficiency Particulate Air (HEPA) filters can function optimally. Verify that air change rates meet industry standards—typically 20-30 air changes per hour in cleanrooms.

Laminar airflow hoods must deliver consistent airflow to maintain product sterility. Monitor exhaust airflow to prevent the accumulation of volatile organic compounds (VOCs). Ensure air handling systems undergo routine maintenance and validation. Document airflow patterns to identify any anomalies or areas of concern.

Pressure Differentials

Without proper oversight, fluctuations in pressure between cleanrooms and adjacent spaces allow contaminants to infiltrate or hazardous materials to escape containment. Falling below the recommended 10-15 pascals establishes safety risks and deviations that could exacerbate these issues.

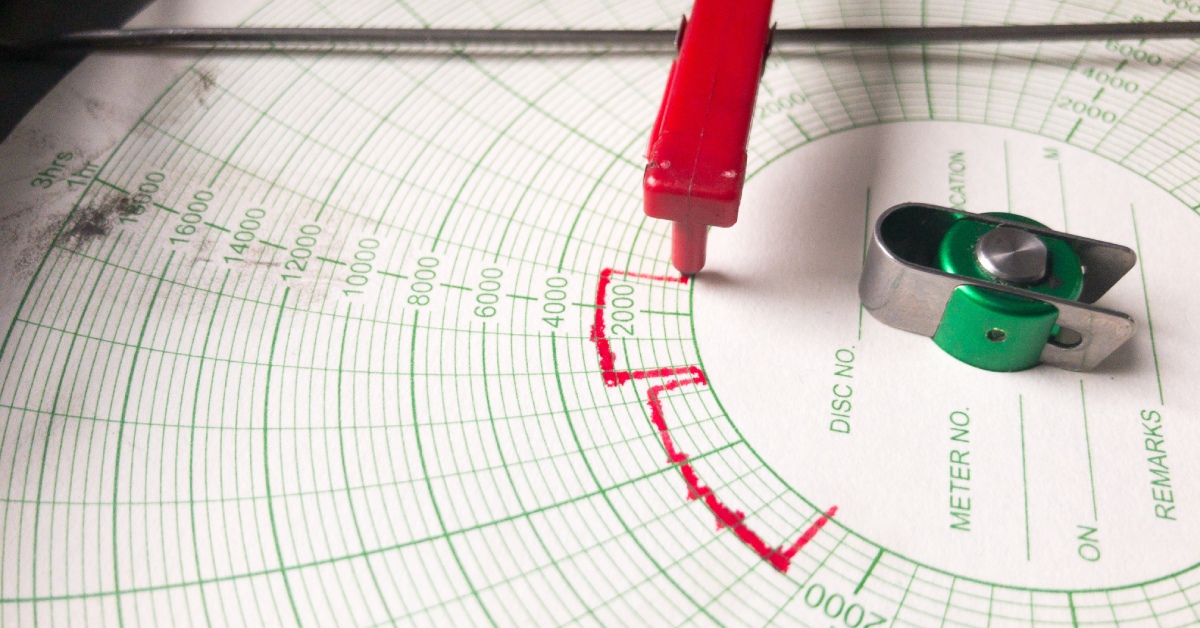

Implementing circular chart recorders is a vital step toward gaining control over the environment and guaranteeing that the workspace is reliable and pharmaceutical products are safe.

Light Intensity

Excessive light intensity can cause photo-degradation of light-sensitive pharmaceutical compounds, leading to a reduction in potency and efficacy. Prolonged exposure may also trigger chemical reactions that produce harmful by-products.

Place lux meters at strategic points within storage and manufacturing areas to capture accurate light exposure data. The lux meters can connect to chart recorders that continuously log illumination levels for a comprehensive record. Regularly review the chart recordings to ensure light intensity falls within the proper range.

Water Quality

The pharmaceutical sector heavily relies on water. It’s a critical element often employed as a base, constituent, and dissolving agent during the creation, formulation, and production of medicines, APIs, intermediates, and diagnostic chemicals.

Different grades of water, such as Purified Water, Water for Injection (WFI), and Sterile Water, are used throughout the manufacturing process. Continuous monitoring upholds the standards to produce excellent products.

Conductivity and pH

Without closely tracking conductivity and pH levels, the quality of water may jeopardize the efficacy of pharmaceutical products. Pharmacists must establish the water’s ionic purity and chemical stability.

Conductivity levels must meet strict limits, typically below 1.3 µS/cm for Purified Water and 0.25 µS/cm for WFI, to prevent contamination. pH levels should stay within 5.0 to 7.0 to maintain product integrity.

Total Organic Carbon (TOC)

Total Organic Carbon measurement helps in assessing the levels of organic impurities in water, which could arise from natural sources or introduced contaminants. TOC analyzers are essential tools for continuous monitoring. TOC levels should meet the regulatory guidelines—generally less than 500 ppb for Purified Water and WFI.

Gas Concentrations

Observing gas concentrations is essential for product quality and personnel safety. Gases such as carbon dioxide, oxygen, and nitrogen can impact pharmaceutical processes and storage conditions. The duo of gas detectors and a continuous monitoring system, such as a Foxboro circular chart recorder, will uphold a secure environment.

Carbon Dioxide

For CO₂, elevated concentrations affect the pH levels of culture media in biopharmaceutical manufacturing. Keep CO₂ levels controlled in incubators and cell culture environments. Target CO₂ concentrations range between 5 and 10 percent.

Oxygen

Maintaining appropriate oxygen levels is crucial in anaerobic processing and preserving the integrity of oxygen-sensitive products. Utilize oxygen-depleting systems to maintain low O₂ concentrations where necessary. The typical target range for O₂ levels is between 0.5 and 2 percent for anaerobic environments.

Nitrogen

Tracking nitrogen (N₂) will prevent oxidation and maintain product integrity. Without adequate monitoring, unwanted chemical reactions such as oxidation can occur, compromising product quality and stability. This can result in discoloration, spoilage, and even hazardous conditions.

The Risks of Improper Environmental Monitoring for Pharmaceuticals

There is a plethora of problems that can ensue without continuous monitoring. Read on to explore some hazards in the pharmaceutical industry that demand measurement to protect products, patients, and employees.

Pharmaceutical Product Contamination

Failing to monitor parameters including temperature, humidity, and air quality can result in contamination. Compromised products hinder patient safety and could have severe health consequences.

Pharmaceutical product degradation may not seem immediately apparent. Even slight deviations from specified conditions can degrade the efficacy of medications. It’s vital to be proactive and conduct detailed monitoring to prevent contamination.

Microbial Growth

Microbial growth is a major concern for product and manufacturing area contamination. It compromises drug sterility, rendering them unsafe, and can also spoil raw materials and finished products.

Regular monitoring is crucial for maintaining conditions that inhibit microbial growth. Ignoring this can result in frequent shutdowns and cleaning cycles that disrupt production schedules.

Non-Compliance With Regulatory Standards

The pharmaceutical industry operates under stringent regulations to ensure product safety and efficacy. Regulatory bodies such as the FDA and EMA enforce strict environmental guidelines.

Failure to comply can result in severe consequences, including hefty fines and sanctions. Legal actions and lawsuits may further strain a company’s financial resources. Poor monitoring can lead to failed inspections, complicating future approvals.

Health Hazards for Workers

Without adequate environmental monitoring, poor air quality in pharmaceutical manufacturing environments can pose significant health risks to employees. Continuous exposure to airborne contaminants, such as chemical vapors, dust, and particulate matter, can lead to chronic respiratory conditions, including asthma and bronchitis.

In addition to impacting lung function, these contaminants can cause eye irritation and headaches and exacerbate existing health issues. Long-term exposure to certain hazardous substances may even increase the risk of cardiovascular diseases and other serious health conditions.

Implement Chart Recorders for a Productive and Protected Environment

Effective pharmaceutical environmental monitoring is only feasible with the right tools. Chart recorders accurately gather information in a physical format. When the chart paper is ready to read, the system operates without intervention and will provide all the details pharmacists need to develop pharmaceuticals.