8th Jul 2024

Why Is the Temperature of Pharmaceuticals Measured?

Keeping products at the right temperature is a necessity in many industries. For instance, the pharmaceutical sector relies on precise temperature measurements for products. Temperature control during storage and transportation ensures that medications reach patients in their most effective form.

There’s more to uncover about the safety and logistics of monitoring the temperature of medication. Let’s dive into the reasons why it’s essential to measure the temperature of pharmaceuticals.

Guarantee the Effectiveness of Medication

Medications have unique chemical compositions, and extreme heat or cold can cause active ingredients to break down. Even slight temperature fluctuations are dangerous because medications can deteriorate or lose their potency. As a result, patients could receive ineffective treatments or consume drugs with hazardous properties.

By maintaining appropriate storage temperatures, healthcare facilities ensure that medications retain their intended potency and effectiveness throughout their shelf life. This practice safeguards patient health and supports optimal treatment results.

Maintain Product Integrity

Pharmaceuticals are subject to degradation processes, such as hydrolysis, oxidation, and photolysis, due to temperature fluctuations. Temperature management prevents the degradation process. Pharmaceuticals including biological drugs, blood products, insulin, and vaccines are highly temperature sensitive and become compromised by improper storage conditions.

Prioritize Patient Safety

Temperature control protocols are integral for eliminating the risk of administering compromised medications. Drugs in inappropriate storage conditions can compromise patient treatment plans. By monitoring and controlling the temperature of pharmaceuticals, healthcare workers can provide safe and effective treatment.

Support Drug Development

The early stages of drug discovery require precise conditions to conduct experiments and develop reproducible results. Temperature management supports consistent reaction conditions, which is vital for the integrity of data generated during preclinical research.

Deviations from the recommended storage conditions during clinical trials could compromise the integrity of the results. Inaccurate conclusions put patients at risk and hinder the drug’s performance.

Prevent Pharmaceutical Product Recalls

Temperature mismanagement can lead to product recalls, which are both financially burdensome and damaging to a pharmaceutical company’s reputation. Recalls can occur when pharmaceuticals are ineffective or unsafe due to improper storage, leading to degraded or contaminated products. Avoiding costly recalls is paramount for pharmaceutical companies and healthcare facilities.

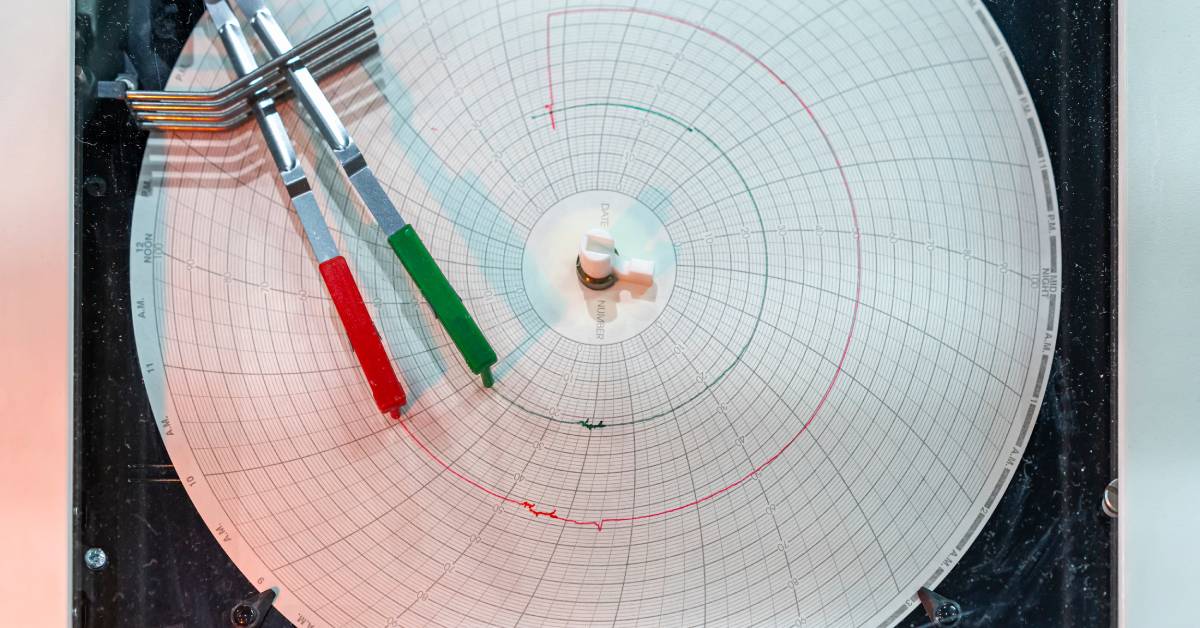

Close temperature monitoring plays a vital role in preventing recalls from ever happening. Devices like the Honeywell circular charts provide continuous, real-time data monitoring. Pharmacists will receive instant alerts when temperature deviations occur. Then, they can take swift corrective action before the products sustain damage.

Reduce Product Waste

Pharmaceutical products are deemed unsafe for medical use when exposed to improper temperatures for prolonged periods. Discarding impaired pharmaceuticals causes financial loss for companies and wastes valuable resources.

Storing medications in ideal temperature conditions helps healthcare facilities and pharmaceutical processing companies reduce the accidental decline of drugs. Consistently monitoring temperatures in medication storage areas is the most effective approach to conserve resources and maintain an efficient supply chain.

Lengthen the Shelf Life of Pharmaceuticals

Temperature regulation is especially important for cold storage medications. Continuous monitoring is the key to prolonging their efficacy and preventing degradation.

For medications that do not require cold storage, maintaining a stable temperature is equally important. These drugs have a broader acceptable temperature range but are still susceptible to deterioration if exposed to extreme heat or humidity over extended periods.

Implementing rigorous temperature control protocols, such as using climate-controlled storage facilities and monitoring environmental conditions, ensures these medications remain within their optimal storage conditions. This proactive approach prevents the breakdown of active ingredients and preserves the therapeutic effectiveness of medications throughout their intended shelf life.

Adhere to National and Worldwide Regulations

Pharmaceutical companies and healthcare facilities operate under stringent regulatory frameworks that mandate storage conditions for medications. Regulatory agencies, such as the Food and Drug Administration (FDA) and the World Health Organization (WHO), set guidelines to ensure the safe storage, handling, and transportation of pharmaceuticals. These standards protect patient health and ensure medications meet criteria for quality and safety.

Compliance with these regulations is not optional; failure to adhere can result in serious legal repercussions, including fines, recalls, and loss of licenses. By maintaining precise temperature control, pharmaceutical companies and healthcare facilities align with regulatory requirements and ensure the availability of safe and effective medications to the public.

Follow Quality Control Requirements

Quality control extends beyond meeting regulatory mandates; it involves the implementation of internal protocols that guarantee the reliability of pharmaceutical products. Companies may employ advanced monitoring systems to track and document storage temperatures in real time. Then, workers can correct any deviations. This attention to detail safeguards against potential temperature-induced degradation.

Additionally, temperature management is an integral part of the universally recognized Good Manufacturing Practice (GMP) that guides the production and distribution of pharmaceuticals. Through meticulous adherence to these quality control measures, healthcare facilities and pharmaceutical companies uphold high standards of patient care.

Ensure Safety During Transportation

Companies in the pharmaceutical industry must also sustain the ideal temperature range for medication during transportation. Here’s a quick rundown of maintaining cold storage and monitoring temperatures in real time.

Cold Storage

Cold chain logistics refer to the transportation of temperature-sensitive products, such as vaccines and insulin. Maintaining an unbroken cold chain is essential because temperature deviations can compromise the efficacy and safety of these pharmaceuticals. Advanced refrigeration units, insulated containers, and dry ice are common in cold chain logistics to maintain the temperature range.

Real-Time Temperature Monitoring

Chart recorders are also useful during transportation. Link the device to a centralized system to provide instant alerts in case of temperature deviations. Monitoring the temperature of products during transportation guarantees they reach their destination in optimal condition.

Temperature measurement is essential for pharmaceuticals. However, you cannot accomplish this task without equipping a dynamic chart recorder to monitor the temperature 24/7. At Chart Recorders and Pens, shop the best brands in the industry, like Honeywell and Partlow, for reliable temperature tracking. Browse the different models, accessories, and replacement parts to make your chart recorder last.

There’s nothing like having a chart recorder up and running to keep the pharmaceutical industry safe and productive. Call or email us with any questions, and start documenting detailed temperature records for pharmaceuticals today!